In the competitive plastic bag manufacturing industry, choosing the right sealing and cutting machine can make or break your production efficiency, product quality, and profitability. Yet, many manufacturers are still using machines that aren’t optimized for their materials or bag types, leading to excessive downtime, waste, and quality issues.

Why the Right Sealing and Cutting Machine Matters

Whether you’re working with HDPE, LDPE, PP, PET, or biodegradable plastics, your machine’s sealing and cutting capabilities directly affect:

- Seal strength and reliability – Poor seals lead to product rejection, customer complaints, and lost trust.

- Cutting precision – Inaccurate cuts cause material waste and inconsistent product dimensions.

- Production speed and automation compatibility – Modern machines must support high-speed operation and integration with auto-stackers, printers, and more.

Ask Before Choosing Your Sealing and Cutting Machine

Ask yourself:

- What materials are you using? Biodegradable compounds require precise temperature and timing control.

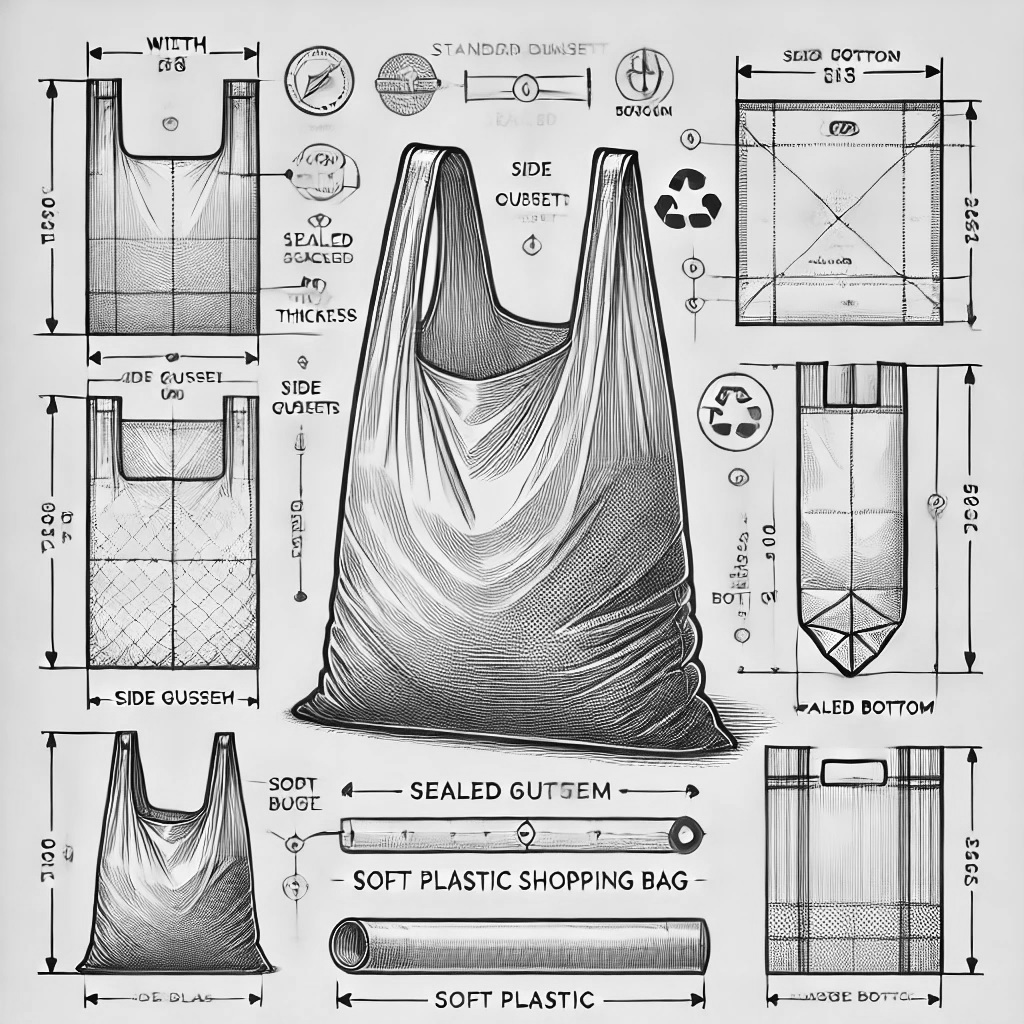

- What bag types do you produce? T-shirt, side-seal, star-seal, or three-side seal bags all require different sealing mechanics.

- What is your production volume? High-speed lines require machines that are fast and stable.

Common Types of Bag Sealing and Cutting Machines

| Machine Type |

Suitable Materials |

Phasellus non | Key Advantages |

| Hot Cutting Machine |

HDPE, LDPE |

T-shirt bags, grocery bags | Strong seals, high-speed output |

| Cold Cutting Machine | PP, biodegradable film | Stationery bags, packaging bags | Clean cuts, no heat distortion |

| Servo-Controlled Machine | All materials | Custom bags | High precision, low maintenance |

| Multi-Function (e.g. Perforation & Roll-Type) | LDPE, HDPE, bio-compounds like NuPlastiQ® | Roll bags, trash bags | Supports perforation & continuous roll production |

How to Choose the Right Plastic Sealing and Cutting Machines?

Customized Design for Diverse Bag Types and Materials

Each customer has unique requirements when it comes to bag size, material type, and application field. That’s why our machines are designed with flexibility and customization in mind.

We support a wide range of plastic films, including:

- LDPE (Low-Density Polyethylene)

- HDPE (High-Density Polyethylene)

- PP (Polypropylene)

- PET (Polyester Film)

- Biodegradable materials (e.g., PLA, starch-based films)

Whether you produce T-shirt bags, flat bags, garbage bags, or courier bags, we tailor each machine to your specifications, ensuring compliance with professional standards.

High-Precision Manufacturing Ensures Quality and Efficiency

The precision craftsmanship and stringent quality control are the foundation of the equipment's stability and durability, ensuring efficient operation in various production environments. This meticulous manufacturing process not only enhances product performance but also effectively reduces maintenance needs and energy consumption during operation. Our automatic plastic bag making machines are built using advanced manufacturing technology and undergo rigorous quality control at every stage. Key advantages include:

- High-speed and stable sealing and cutting performance

- Precise tension control and material feeding

- Low maintenance and long machine life

- Energy-efficient operation

These features allow manufacturers to operate efficiently in both high-volume and specialized production environments.

What Else to Consider When Choosing Your Sealing Cutting Machines

Smooth Delivery, Installation, and Technical Support

Delivery and installation are critical for the smooth startup of a production line. From production line setup to precise equipment calibration, every step is fully supported by a professional technical team to ensure the equipment quickly reaches optimal operating conditions. On-site support and technical guidance help customers quickly master equipment operation, further enhancing production efficiency.

Continuous Service and Support: Building Long-Term Partnerships

The operation of the equipment is just the beginning. Stable technical support and maintenance are key to long-term efficient production. From daily maintenance to technical upgrades, our services are aimed at ensuring the stable operation of the equipment. The technical team also assists in training customer staff, equipping them with basic maintenance skills to handle daily maintenance needs. This ongoing support helps customers maintain a competitive edge in a changing market and during technological innovations.

Frequently Asked Questions (FAQs)

A: It depends on your film type (e.g., HDPE vs PLA). Our technical team offers guidance based on your production specs and material behavior under heat and pressure.

A: Yes. Our multi-function sealing and cutting machines are designed to adapt to different bag types with modular components and flexible programming.

A: Our machines are upgrade-ready and compatible with a range of bio-films like PLA and NuPlastiQ®. You can switch without major hardware changes.

A: Typically 2–5 days depending on complexity. Our engineers provide on-site installation, calibration, and staff training to ensure a smooth transition.

Note: For precise machine configuration, material compatibility, and application suitability, please consult our technical team for a tailored evaluation based on your productio

A Complete Solution for Plastic Bag Production Line

Parkins’ plastic bag-making machines are more than just equipment, they are part of a complete, integrated solution that supports your growth, sustainability, and production excellence. From customized design to long-term support, we are committed to helping you stay competitive in the dynamic bag-making market.

Looking to upgrade your plastic bag production line? Contact our experts today to discuss your specific needs and get a free consultation.