Whether you're producing T-shirt bags, ziplock pouches, or bag-on-roll formats, a fully automatic plastic bag making machine is essential for efficient, high-volume production. In this guide, Parkins breaks down how these machines work, what features matter, and how to choose the right solution for your production needs—from foundational basics to advanced automation insights.

Understanding the Role of an Automatic Plastic Bag Making Machine

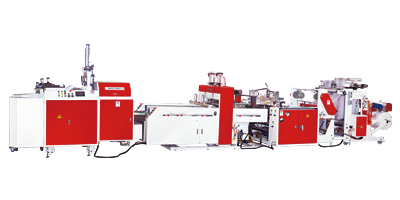

An automatic plastic bag making machine transforms plastic film rolls—such as LDPE, HDPE, biodegradable, or recycled materials—into finished bags with minimal operator involvement. These systems are designed for continuous, high-speed, and repeatable output.

Unlike manual or semi-automatic lines, fully automatic machines eliminate the need for manual film feeding, sealing adjustment, cutting, and stacking. Instead, the entire process is integrated into one streamlined operation, including:

- Automatically unwinding and tension-controlling film for smooth feeding

- Aligning printed marks with photoelectric sensors for accurate logo placement

- Cutting and sealing with servo control for precise, high-speed results

- Auto-stacking, folding, or rewinding based on bag type

- Modular add-ons such as die punching, handle punching, or zipper sealing modulespe

By integrating all these functions, an automatic bag making machine delivers:

- Uniform bag dimensions and strong, clean seals

- Output speeds up to hundreds of bags per minute

- Reduced film waste and human error

- Seamless compatibility with printing or downstream packaging lines

- Smart control interfaces that store settings and enable fast changeovers

For manufacturers aiming to reduce labor dependency, accelerate production cycles, and maintain consistent quality at scale, automation is no longer a luxury—it’s a necessity.

Key Features to Look For

When investing in an automatic plastic bag making machine, understanding the automation-driven design features is crucial. Here’s what to prioritize:

● Servo Motor Control

Precision matters. Servo systems enable highly accurate sealing and cutting, even at full production speed. They reduce mechanical wear, increase line stability, and simplify fine-tuning.

● Touchscreen Control Panel

Operator-friendly interfaces allow real-time adjustments to sealing temperature, bag length, and production speed. Pre-set recipes streamline changeovers, especially for factories with multiple SKUs.

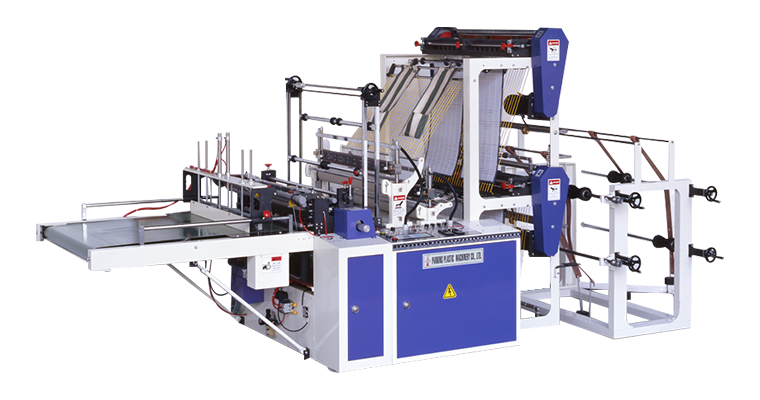

● Multi-Lane Flexibility

Machines that support 2 to 12 lanes can produce multiple bags per cycle, drastically increasing output without expanding floor space. Perfect for small-format bags in FMCG or medical applications.

● Photoelectric Tracking

Sensors detect film marks to align printed artwork with sealing and cutting points—ensuring high visual consistency across thousands of bags.

● Film Compatibility

Supports a range of film types:

- LDPE and HDPE for everyday use

- Biodegradable materials (PLA, PBAT) for eco-focused lines

- Recycled films for sustainable packaging goals

With adjustable temperature zones and tension control, Parkins machines handle both lightweight and heavy-duty films with ease.

● Modular Expandability

Equip your machine with:

- Zipper sealers

- Die-cut handles

- Gusset formers

- Hole punching or hanger tabs

These options allow customization without a complete system overhaul.

Automatic Stacking, Folding & Rewinding

Automating post-process steps further reduces manual handling. Bag-on-roll machines with coreless rewind save both material and labor in high-volume produce or pet waste packaging.

Energy Efficiency & Safety

Next-gen systems feature:

- Energy-efficient heating systems with smart temperature control

- Servo over pneumatic for quieter, cleaner operation

- Safety enclosures, emergency stop functions, and smart fault alerts

📌 Tip: Don’t just look at bags per minute—also consider how automated features reduce downtime, waste, and dependency on skilled labor.

Bag Types and Recommended Machine Models

Parkins offers a full portfolio of fully automatic bag making machines designed for diverse applications:

| Bag Type |

Application |

Recommended Machine Model |

| T-shirt Bags |

Supermarkets, grocery chains |

Double-Lane Fully Automatic Servo-Control High Speed T-Shirt Bag Making Machine |

| Multi-lane Flat Bags | FMCG, snack packs | 6-Lane Fully Automatic Servo-Control Double Decker Cutting Sealing Machine |

| High-Output Seal Bags | Food packaging, export lines | Double Layer 8-Lane Fully Automatic Servo-Control Sealing & Cutting Machine |

| Bag-on-Roll (Produce) Bag-on-Roll (Pet Waste) | Produce, fresh food packaging Pet waste collection, waste management | Double-Lane with Core Fully Automatic Servo Control Perforating Bag-on-Roll Machine Sealing & Perforating pet waste Bag on roll making machine (separate machine due to size differences) |

| Disposable Gloves | Healthcare, food service | Electronic High-Speed Fully Automatic Glove Type Making Machine |

Each unit is servo-driven, operator-friendly, and built for long-term industrial performance.For a detailed breakdown of machine recommendations by industry—such as bakery, e-commerce, and heavy-duty packaging—see our companion article : Best Plastic & Polythene Bag Making Machines by Industry (2025 Guide).

Manual, Semi-Automatic, or Fully Automatic: Which Bag Making Machine Fits Your Needs?

Not all bag making machines are created equal—and neither are the factories that use them. Whether you're operating a small workshop, managing a mid-sized production line, or scaling up for export-level demand, choosing the right level of automation directly impacts your output, labor efficiency, and production flexibility.

In this section, we compare the key differences between manual, semi-automatic, and fully automatic plastic bag making machines to help you identify the best solution for your operation. From operator involvement and speed to sealing precision and expansion potential, here’s how each option compares—and why more factories are making the move to fully automated systems like those from Parkins.

Machine Comparison Table

| Function / Automation Level |

Manual or Standard Machine |

Semi-Automatic Machine | Fully Automatic Machine (Parkins) |

| Film Feeding |

Manual roll loading |

Motor-driven, speed adjustment is manual | Fully automatic with tension control and adjustment functions. |

| Sealing & Cutting | Heat bar or hot knife in the machine; operator manually aligns film and starts the cycle. Cutting is machine-driven but needs manual feeding. Quality relies on operator precision. | Pneumatic with limit switches | Servo-controlled with digital settings |

| Operator Involvement | Constant, multi-step | Moderate, per cycle adjustment | Minimal, pre-set & programmable |

| Output Speed | 30–60 bags/min | 80–120 bags/min | Up to 400 bags/min (model dependent) |

| Bag Consistency | Varies by operator | Moderate | Precise, repeatable |

| Film Compatibility | Basic films (LDPE/HDPE) | Limited to thin films | Supports LDPE, HDPE, |

| Add-on Functions (zipper, punch) | Not available | Limited | Modular expansion supported(software and control system pre-designed for future add-ons; hardware must be ordered at purchase and cannot be retrofitted later) |

| Ideal For | Small workshops, low budget | Growing production lines | High-output factories & export needs |

Manual and semi-automatic machines still have their place in low-volume or budget-conscious operations, but they often create bottlenecks in consistency, labor efficiency, and speed.

In contrast, fully automatic systems—like those engineered by Parkins—deliver long-term reliability, reduced labor costs, and flexibility for multi-format bag production. When speed, precision, and scalability matter, automation is the clear choice.

Why Automation Matters in Plastic Bag Production

Today’s factories face tighter delivery windows, higher labor costs, and growing demand for customized packaging. Automation addresses these challenges by enabling:

- Faster, more consistent output

- Lower manpower requirements

- Smarter control over quality variables

- Easier compliance with export and hygiene standards

- Future-proof upgrades through modular design

The shift from manual to automatic isn't just about speed—it’s about long-term profitability, efficiency, and factory scalability.

Is an Automatic Machine Right for You?

If you're producing more than 50,000 bags per day, working with multiple bag types, or facing rising labor pressure, a fully automatic system will pay for itself. These machines are ideal for:

- OEMs and contract manufacturers

- High-volume food packaging suppliers

- E-commerce mailer bag producers

- Plants expanding into sustainable materials

With pre-programmed settings, real-time adjustments, and automated downstream handling, Parkins automatic machines reduce the friction between production goals and factory realities.

Build Your Bag Production Line with Parkins

With 30+ years of engineering expertise, Parkins delivers fully automatic plastic bag machines, trusted by leading manufacturers worldwide across food, retail, logistics, and industrial packaging sectors. We don’t just sell machines—we help design full automation strategies that grow with your business.

Our team supports:

- Machine selection based on your bag types

- Layout consultation and capacity planning

- Installation, training, and ongoing service

Ready to Automate with Confidence?

Whether you're sourcing a:

- T-shirt bag making machine for retail and grocery

- Multi-lane flat bag unit for small format packaging

- High-speed bottom seal machine for industrial liners

- Bag-on-roll line with automated rewinding

- Glove-type bag machine for disposable hygiene products

Parkins offers fully automatic solutions engineered for speed, flexibility, and long-term performance—tailored to match your unique production goals.

Ready to explore the best-fit machine for your application?

Contact our automation experts to walk you through model selection, performance benchmarks, and layout planning—we’ll guide you every step of the way.