As the global push toward sustainable packaging intensifies, the UK has strengthened its environmental policies by updating the Plastic Packaging Tax (PPT). Starting April 1, 2025, the tax will increase to £223.69 per metric ton, applying to any plastic packaging that contains less than 30% recycled content.

For packaging manufacturers looking to avoid this cost and meet new buyer expectations, the shift toward biodegradable and compostable films like NuPlastiQ® and PLA is becoming essential. This change is driving strong demand for bag-making machines that can reliably process these next-generation materials. If you're seeking equipment that supports eco-friendly film production while maintaining performance and efficiency, now is the time to invest in machines that are built for sustainability compliance.

What Is the Plastic Packaging Tax (PPT)?

Introduced in 2022, the UK’s Plastic Packaging Tax aims to reduce single-use plastic waste and encourage the use of recycled materials in packaging.

Key points to note:

- The tax applies to plastic packaging manufactured in or imported into the UK.

- It affects packaging with less than 30% recycled content by weight.

- From April 1, 2025, the rate is increasing to £223.69 per ton.

- Businesses that fail to comply may face significant financial penalties.

This regulation drives companies to reevaluate not only the materials they use but also the type of machinery they need to produce compliant packaging.

Why Compostable Film Compatibility Matters for Bag Producers

The demand for machines that support compostable and recycled materials is no longer optional; it’s a business imperative. UK packaging converters, importers, and retailers are urgently seeking ways to:

- Replace traditional PE/PP with certified compostable films

- Integrate NuPlastiQ® blends, PLA, or PBAT into their existing packaging lines

- Ensure consistent sealing, cutting, and bag integrity with these new substrates

Clients now demand machinery that supports more complex, often less stable materials, without sacrificing speed, sealing strength, or product consistency.

How Parkins Bag Making Machines Support PPT Compliance

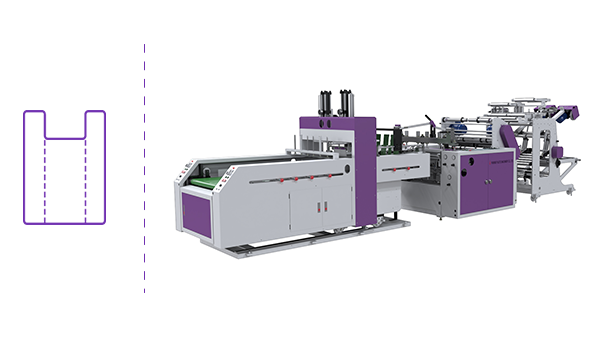

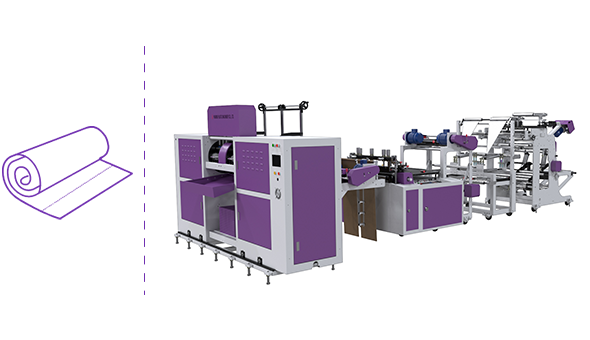

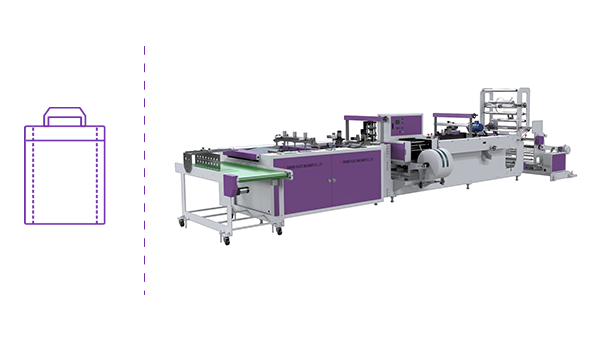

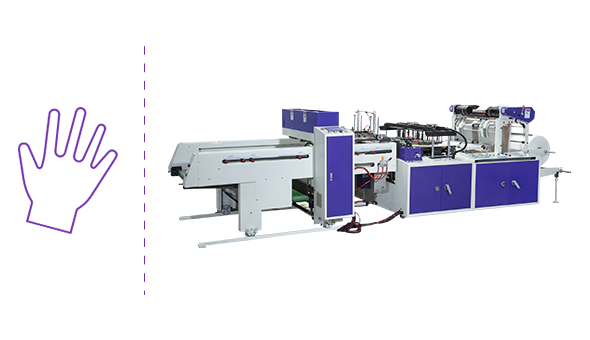

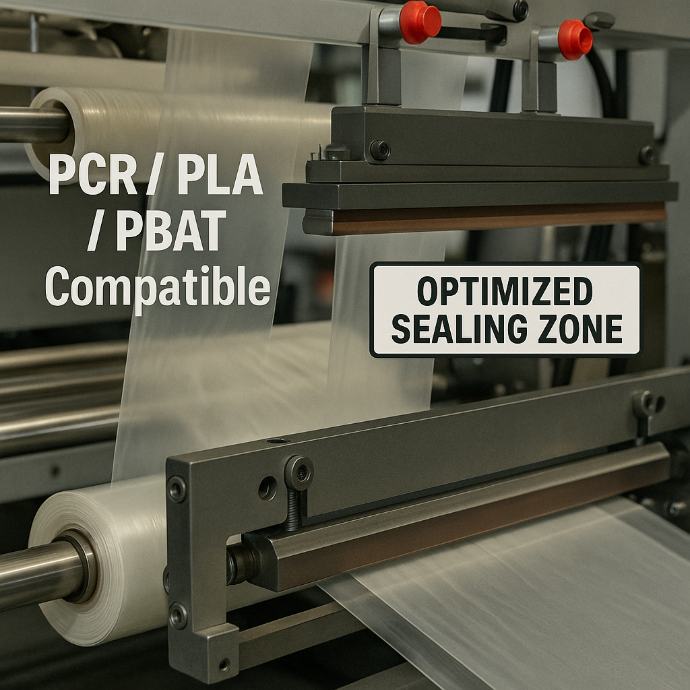

Parkins has designed and refined our bag-making machines to handle the unique requirements of sustainable and recycled materials. Whether you’re working with NuPlastiQ®, PLA, PBAT, or other sustainable substrates, our biodegradable bag making machines help you achieve reliable output with consistent quality. Here’s how our equipment helps UK converters adapt:

- High Compatibility: Our machines can process PCR film (up to 50%), PLA, PBAT, and other biodegradable film structures with stability and efficiency.

- Precise Temperature Control: Helps maintain optimal sealing even with materials sensitive to heat variation.

- Advanced Tension & Cutting Systems: Designed to manage the lower tensile strength of recycled and compostable films.

- Custom Configurations: For clients transitioning to new material blends, we offer tailored adjustments and on-site testing support.

Whether you’re producing compostable shopping bags, PLA trash liners, or PCR-based packaging film, our machines are ready to meet these new challenges head-on.

Meeting Sustainability Regulations Doesn’t Have to Slow You Down

Switching to compostable or recycled films doesn't mean compromising productivity. With the right machinery, you can scale up your sustainable packaging line without sacrificing speed or efficiency. We understand that regulatory shifts like the UK PPT are not just compliance issues, they’re also market opportunities. Our role is to empower packaging manufacturers to turn this shift into a competitive advantage.

We work closely with material suppliers and converters to:

- Test new materials on our machines

- Recommend optimal sealing & cutting settings

- Provide post-installation training for new substrates

- Ensure long-term equipment compatibility with future packaging trends

By investing in equipment that’s future-ready, you're not only staying compliant but gaining a powerful edge in a market that’s increasingly demanding accountability.

Turn Compliance into Competitive Advantage

The 2025 update to the UK Plastic Packaging Tax is accelerating a shift that was already underway: the move toward eco-friendly, compliant packaging. Whether you're serving UK clients or exporting to Europe, being able to produce packaging with biodegradable, compostable, or high-PCR content is a major differentiator.

At Parkins, we make this shift easier. Our plastic bag manufacturing machines are already working successfully with NuPlastiQ®, PLA, and similar sustainable materials, and we’re ready to help you do the same.

Want to learn more about our bioplastic bag-making machine solutions?

Contact us today to get technical details, arrange a material test, or receive a customized quote.

You May Also Be Interested In:

How Sealing Machines Enable the Production of Recyclable Plastic Bags

How Steel Improves the Lifespan of Cutting and Sealing Machines