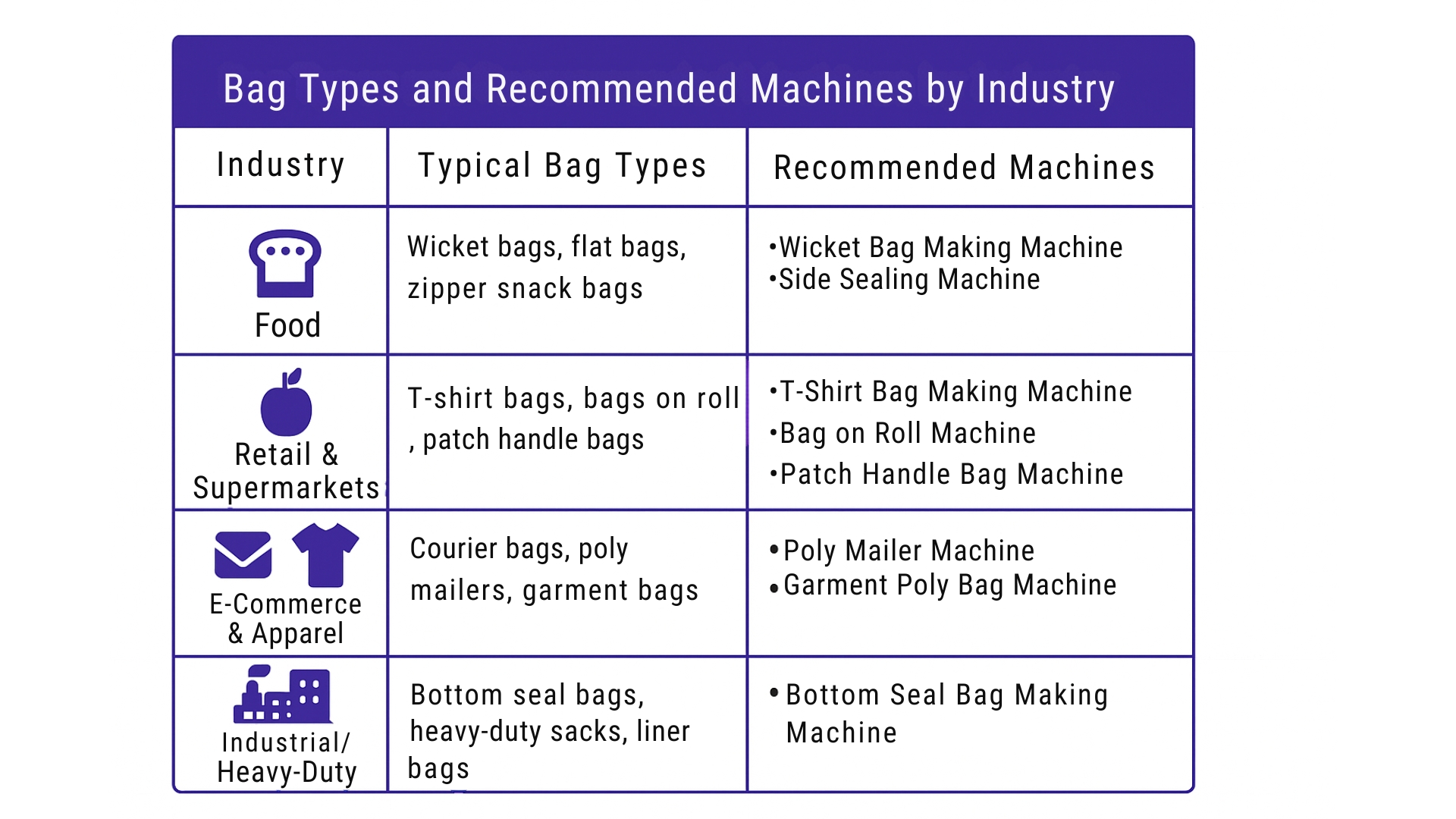

Whether you’re in food packaging, retail, logistics, or sustainable products, choosing the right plastic bag manufacturing machine can significantly impact your production efficiency, bag quality, and operating costs.

In this 2025 expert guide, Parkins outlines the most common plastic and polythene bag types by industry—and the best-fit machines engineered to produce them. From wicket bags for bakeries to tamper-proof courier poly mailers, this guide helps you match materials, sealing methods, and film types with machines built for speed, reliability, and flexibility across LDPE, HDPE, biodegradable, and recycled film formats.

![Best Plastic & Polythene Bag Making Machines by Industry [2025 Guide]](/web/image/5831-96105042/image10.jpg?access_token=d401ebef-a120-4cee-a7bd-9d87b4dc7965)

Why Application-Specific Machines Matter

Plastic and polythene bags may appear simple, but their manufacturing requirements are anything but. Different end uses demand specific material characteristics, sealing methods, and machine configurations:

- Food packaging requires contamination-free sealing, speed, and support for food-grade films.

- Retail bags must be produced at scale while maintaining cost control and durability.

- E-commerce mailers involve tamper resistance, print compatibility, and flexible format design.

- Industrial packaging demands strength, heat-sealed reliability, and optimized palletization for logistics.

Using a machine tailored to the application ensures consistent bag quality, higher yields, and long-term production stability.

Industry Applications and Machine Recommendations

Food Industry – High-Speed, Hygienic Packaging

Typical Applications: Bread bags, frozen food pouches, resealable snack bags

Common Bag Types: Wicket bags, flat bags, zipper bags

Machine Solutions:

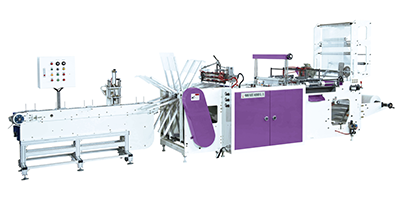

- Wicket Bag Making Machine: Designed for high-speed bakery and food packaging lines, with modular configurations for volume scalability.

- High-Speed Side Sealing Machine: Ensures precision sealing for lightweight food-grade bags.

- Zipper Bag Making Machine: Suitable for packaging formats requiring resealable closures.

Retail & Supermarkets – Cost-Effective, High-Volume Production

Typical Applications: Grocery carriers, convenience store bags, discount chain packaging

Common Bag Types: T-shirt bags, bags on roll, patch handle bags

Machine Solutions:

- T-Shirt Bag Making Machine: Optimized for efficient LDPE/HDPE carrier bag production.

- Bag on Roll Machine: For perforated roll production used in produce and checkout stations.

- Patch Handle Bag Machine: Creates reinforced shopping bags suitable for branding.

E-Commerce & Apparel – Tamper-Proof, Branded Poly Mailers

Typical Applications: Apparel packaging, courier fulfillment, shipping protection

Common Bag Types: Courier bags, poly mailers, garment bags

Machine Solutions:

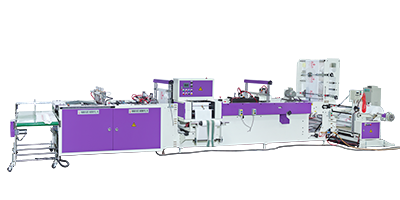

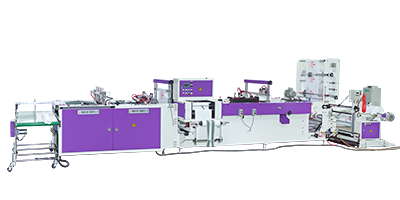

- Courier Bag Making Machine: Designed for tamper-evident, brand-ready poly mailers with options like self-adhesive seals and die-cut handles.

- Poly Mailer Bag Machine: For custom-shaped, print-compatible polyethylene shipping bags.

- Garment Poly Bag Machine: For shirt, dress, and apparel packaging—supports biodegradable films and hanger holes

Industrial & Heavy-Duty Packaging – Durable Solutions for Polythene and Other Load-Bearing Bags

Typical Applications: Fertilizer bags, bulk construction sacks, folded liners for shipping

Common Bag Types: Bottom seal bags, heavy-duty sacks, liner bags

Machine Solutions:

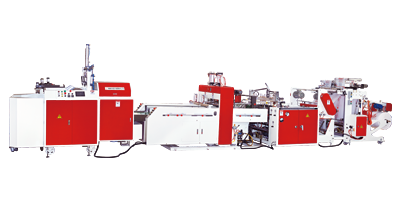

- Bottom Seal Bag Making Machine: Built for heavy-duty, thick-film packaging applications with reliable structural strength.

- Bag Folding Machine: Streamlines folding and stacking of large-format liner bags for bulk logistics.

- Polythene Bag Making Machine: Ideal for manufacturing bags from LDPE and HDPE films, including general-use poly bags, roll bags, and durable sacks.

Polythene Bag Making Considerations

Polythene—commonly in the form of LDPE (Low-Density Polyethylene) and HDPE (High-Density Polyethylene)—is widely used for its strength, flexibility, and cost-effectiveness. Whether you're producing lightweight produce bags, bottom-seal sacks, or industrial liners, selecting the right polythene bag making machine ensures:

- Optimal seal strength and clarity

- Material flexibility across recycled or biodegradable poly films

- Compatibility with high-speed cutting and sealing systems

- Reduced energy use with precise temperature control modules

Parkins offers machines purpose-built for polythene processing, including equipment with modular add-ons for folding, hole punching, die-cutting, and photoelectric sensor detection for pre-printed marks.

Key Engineering Considerations When Selecting a Machine

● Bag Design & Sealing Type

- Side sealing for high-speed lightweight formats

- Bottom sealing for structural strength and large loads

● Material Handling Requirements

- Supports LDPE, HDPE, recycled polythene, biodegradable films

● Production Speed

- Align machine capacity (bags per minute) with production schedules and volume targets

Engineering Tips for Bag Makers and OEMs

Invest in modular machine architecture: Add-ons like die punching, folding stations, or multi-lane modules allow flexible production shifts.

- Choose integrated systems: Cutting-sealing combos and auto-stacking modules reduce floor space and setup time.

- Ensure local service availability: Critical for minimizing downtime in high-throughput environments.

- Stay compliant with evolving regulations: Especially for food contact materials, compostable film certifications, and export standards.

Case in Focus: Performance Upgrade in Southeast Asia

A leading snack food manufacturer in Southeast Asia recently deployed a high-speed side sealing machine with zipper pouch integration. Results include:

- +40% increase in daily output

- Zero deviation in edge sealing quality

- Full compliance with food-grade export packaging standards

Ready to Streamline Your Bag Production?

Choosing the right bag making machine is more than a technical decision—it’s a strategic one. From bakery bags to poly mailers and polythene bags for industrial use, Parkins offers tailored solutions for every application.

Whether you’re sourcing a:

- Polythene bag making machine for LDPE/HDPE general-use bags, utility rolls, or heavy-duty sacks

- T-shirt bag making machine for retail and supermarket use

- Courier bag making machine with tamper-evident sealing

- Plastic bag cutting and sealing machine to boost output flexibility

- Biodegradable plastic bag making machine for eco-conscious brands

We provide full-line support—from product consultation to after-sales service.

Contact our engineering team to explore machine specs, capabilities, or request a polythene bag making machine price comparison.

Browse our machine lineup or schedule a customized consultation.