In an increasingly competitive global market, manufacturers of essential consumables face constant pressure to maximize efficiency while minimizing scrap rate. The performance of your garbage bag making machine is the singular determinant of profitability. Whether optimizing an existing operation or establishing a new production line, gaining a deep understanding of the core technical parameters and market trends, particularly for the garbage bag on roll making machine, is paramount for securing a viable return on investment.

This article provides a professional manufacturing perspective, analyzing the key factors in equipment selection and discussing recognized technical challenges and their solutions in the industry.

Before diving into the analysis: If you are new to the machinery market or require a comprehensive overview of fundamental principles, we recommend starting with our essential guide: Your Guide to Automatic Plastic Bag Making Machines.

For any operation seeking to scale up or optimize production, the choice of a machine must return to the product requirements. Here are the three essential technical parameters to consider when selecting or customizing a bag making machine:

For a detailed technical comparison, see our article on Bottom vs. Side Sealing Bag Machines: Differences, Applications & Selection Guide.

To contextualize the technical parameters discussed above, a comparison of the industry-leading specifications for the garbage bag on roll making machine is essential:

| Specification | Typical Industry Standard | Parkins Maximum Specification |

| Max Output Speed | 120 – 180 cycles/min | Up to 280 cycles/min (Star Seal On Roll) |

|---|---|---|

| Max Bag Width | 800 mm – 1200 mm | Up to 1600 mm |

| Min Film Thickness | 12μm | As low as 8 μm |

You've reviewed the critical technical parameters. Now, see how Parkins transforms these maximum specifications—such as extreme speed and width—into tangible production assets through our advanced servo-control models. Click below to explore the solutions that best match your capacity needs.

| Double-Line Core & Coreless Perforating Bag on Roll Machine | Star Seal Bag on Roll Machine with Labeling Device |

| Twice the output of single-line machines. | Highest speed capability (up to 280 cycles/min). |

| Integrated Core and Coreless Winding. | Precision star sealing for superior leak protection. |

| Ideal for general purpose waste bag production. | Integrated labeling module for retail-ready rolls. |

|

|

|

However, equipment selection goes beyond these fundamental metrics. Manufacturers aiming for specific, high-value products—such as complex star seal models—must also consider the specialized technical demands these varying bag forms place on the machinery.

Star Seal Bags: Requires precise four-point folding and cutting synchronization. The challenge lies in ensuring the center point alignment remains perfect even at high speeds.

Beyond the mechanical constraints of complex bag designs, modern manufacturing faces an even greater frontier: navigating the shift toward sustainable materials. This environmental imperative introduces a new dimension of technical difficulty, particularly concerning material adaptability.

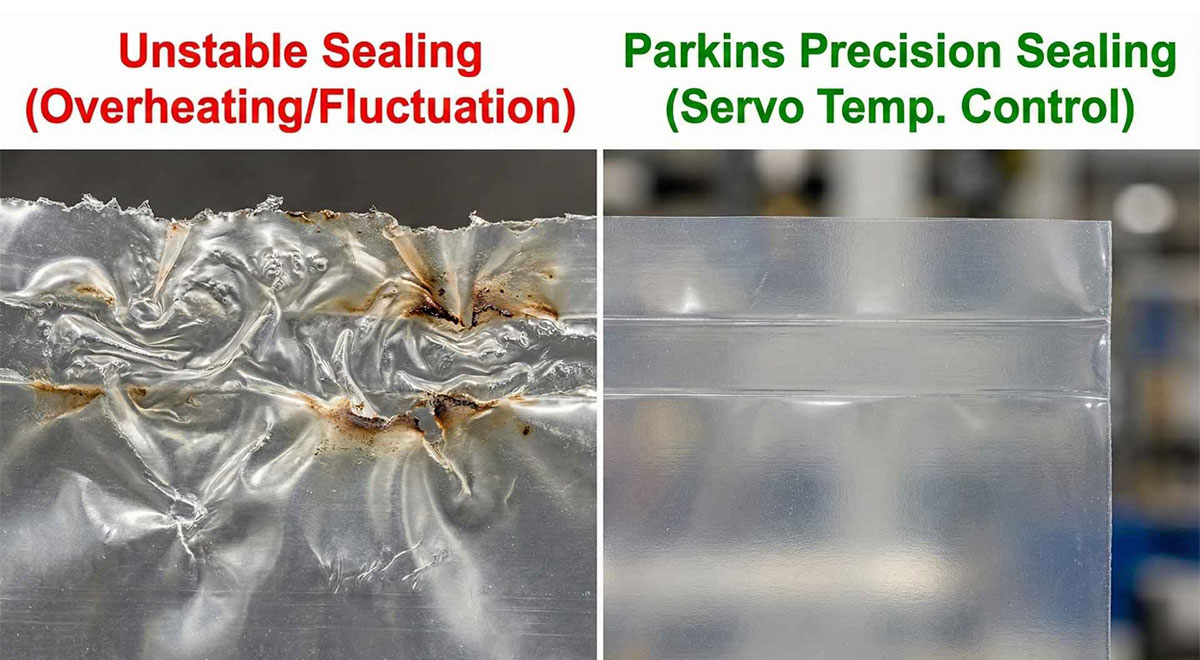

What is the Biggest Technical Adaptability Challenge? – Extreme Temperature Sensitivity

Compared to traditional polyethylene (PE) materials, every type of biodegradable material is extremely demanding regarding temperature control. Their melting range is narrow, and they are highly sensitive to thermal changes:

Expert Insight: It's a common industry saying: "Even a slight temperature fluctuation of 1 ~ 3°C caused by ambient air currents can destabilize the seal." This requires not only a machine with a precise temperature control system but also consideration of the local climate and environment (such as humidity and ambient temperature) during machine design and operation to ensure sealing stability.

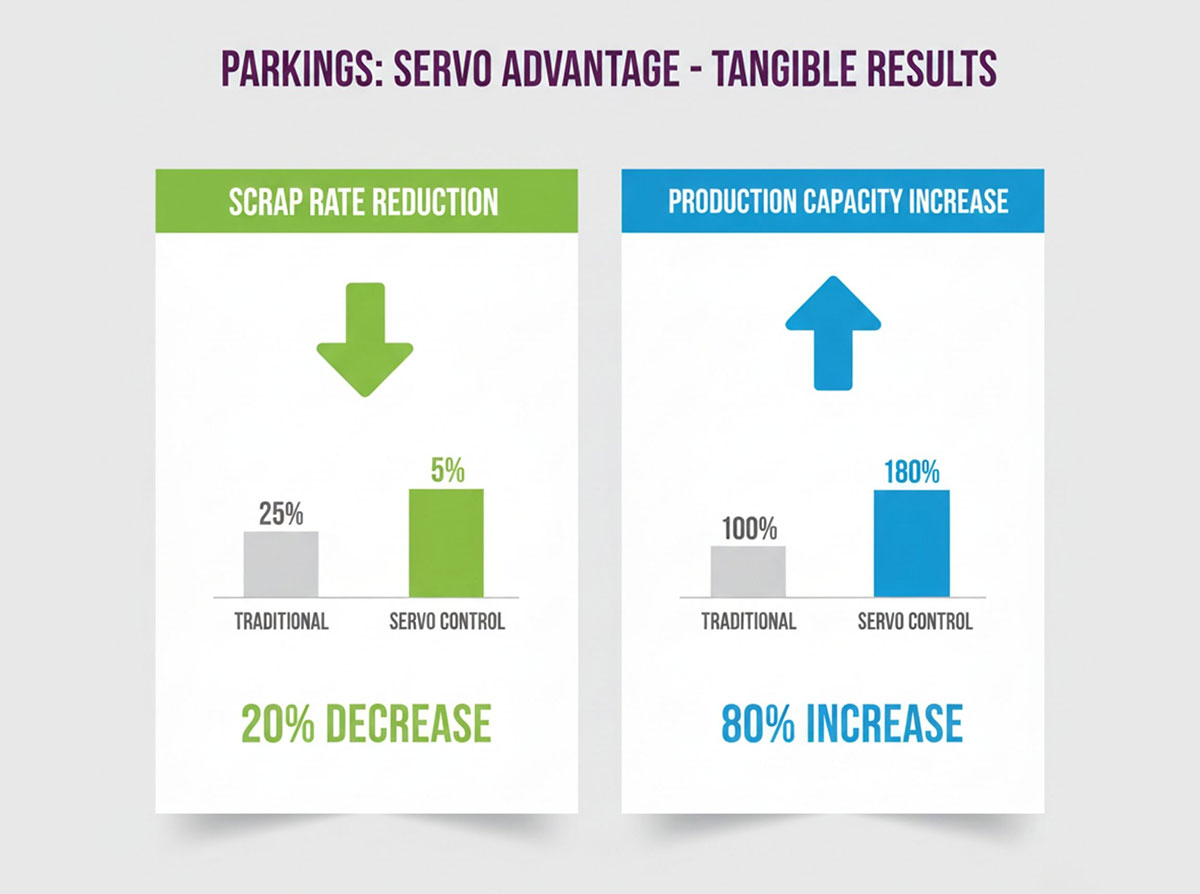

The garbage bag on roll making machines is the mainstream production model due to its high efficiency and automation. However, many manufacturers pursuing high speed also face the dilemma of high scrap rates. To solve this, we must pinpoint the three hidden causes of increased waste, particularly in high-speed roll winding:

Successfully tackling these inherent scrap rate challenges—from perforation inconsistency to roll winding errors—demands technical innovation that transcends traditional machine design. This is precisely where industry-leading solutions, like those provided by Parkins, redefine operational standards.

The enduring client concern over seal integrity is a direct reflection of brand reputation. Addressing this requires a commitment to both advanced machine design flexibility and relentless process optimization.

(Fully Automatic Electronic H.S Sealing & Perforating pet waste Bag on roll making machine)

Choosing a garbage bag making machine is a long-term strategic decision. Beyond the initial price, prospective buyers should focus on long-term operational viability.

We urge you to inquire about these crucial details during the quotation process:

For market insights and industry-specific model recommendations, review the Best Plastic & Polythene Bag Making Machines by Industry.

Parkins' greatest advantage in these bag making machine applications lies in our synchronous design and the close feedback loop established with our clients.

Choosing Parkins is more than an equipment purchase; it's securing a professional technical partner committed to your growth. Through our synchronous design methodology, we don't just sell standard machinery—we collaborate with clients, adapting our technology based on continuous feedback to align maximally with their specific materials, applications, and operating environments. Parking s delivers the customized solution necessary for next-generation manufacturing excellence.

Ready to redefine your production standards? Contact our technical consultants today to discuss your material challenges and customize the optimal bag making solution for your business. Contact Us today!